Jan-April 2023, Sponsored by SAS Institute

Deca foods is a food food distribution company which works on distribution, maintaining stock, looking for trends, and new products they noticed an increase in food not making it to destinations, causing waste due to unexpected weather changes.

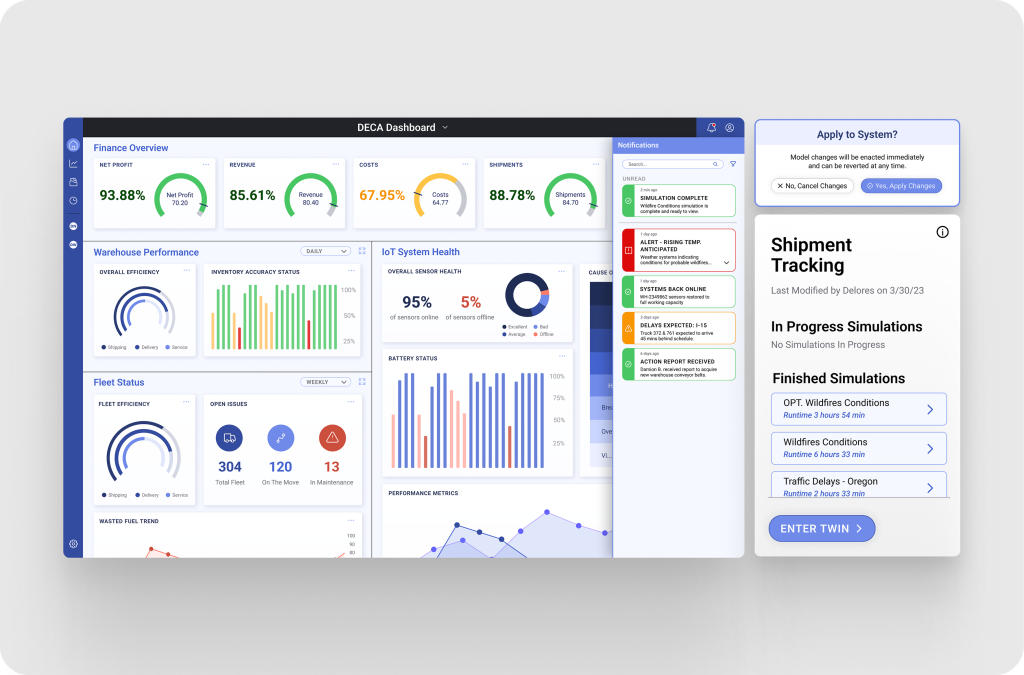

This project aims to provide a logistics management tool to help prevent company losses and reduce food waste by optimizing supply chain efficiency with real-time tracking and AI-recomondation.

Internet of things (IoT): Connects smart devices to share data, enabling automation and real-time monitoring.

Digital Twin: It is a virtual replica of a physical object or system used for real-time monitoring and optimization.

Logistics manager: A logistics manager ensures efficient transportation, storage, and delivery of goods.

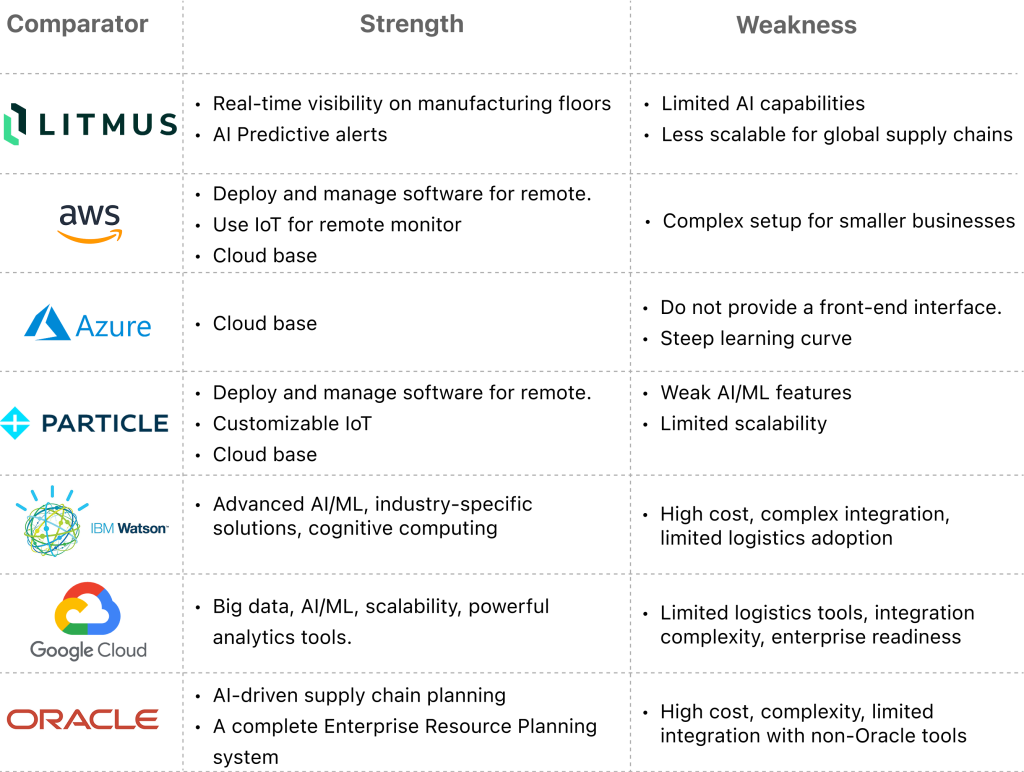

Conducted a competitive analysis to identify opportunities for product differentiation, as competitors of SAS Institute offer supply chain software.

Difficult to connect with existing logistics systems.

Poor interoperability between tools leads to fragmented data.

AI-driven solutions often require specialised technical expertise.

Add real-time tracking to boost supply chain visibility.

Real-time traffic-based route adjustments to reduce delays

Help anticipate supply chain disruptions

“We still rely on spreadsheets, which leads to errors and delays.”

“We’re often playing catch-up instead of being proactive.”

“We’re scrambling during bad weather—better tools could help us plan ahead.”

“We’re constantly dealing with communication breakdowns between teams leading to delays.”

“Data is fragmented, making it hard to make quick decisions.”

“Our systems don’t talk to each other, making it harder to track shipments accurately.”

Dependence on spreadsheets causes inefficiencies.

Dependence on spreadsheets causes inefficiencies.

Fragmented systems impede seamless information flow.

Absence of predictive analytics for planning.

Streamlined processes reduce manual errors.

Digital twins enable proactive scenario planning.

Unified systems enhance decision-making efficiency.

Forecasting tools support proactive logistics management.

##

Deca Foods is facing more frequent food shipment failures, resulting in increased food waste, worsening food equity issues, and impacting profitability.

Implement proactive weather alerts.

Provide AI recommendations based on historical data.

Use digital twins to simulate scenarios and predict optimal actions needs to be taken in advance.

Implement proactive weather alerts.

Provide AI recommendations based on historical data.

Use digital twins to simulate scenarios and predict optimal actions needs to be taken in advance.

This fask flow shows how logistics managers receive an alert about a potential disruption and activate digital twin mode to simulate scenarios, test responses, and estimate losses—enabling proactive, data-driven decisions to reduce food waste.

Sensors(IoT) in a supply chain collect real-time and historical data, which is stored and used to create a Digital Twin—a virtual model of the supply chain.

This Digital Twin helps businesses simulate different scenarios (e.g., demand changes, supplier delays) and predict potential impacts, improving decision-making, efficiency, and risk management.

A digital twin system that leverages AI-driven simulations to predict and mitigate business losses caused by unpredictable weather disruptions.

Model is a dual views shows the hierarchical relationships of simulations to the live system. The branch view specifically shows simulations applied to the live system.

The AI system analyzes live and past shipment data to recommend the best recommendation, helping reduce food waste and business losses. It continuously learns and improves its recommendation over time.

Working on this project, I have gained a new perspective on data. Instead of seeing data as messy or unorganized, I now understand how it can be structured and used effectively in design. Additionally, I have learned that UX design is not only about visuals but also about the data and processes that shape the way information is presented and understood.